A Juan del Llano Special originally published at my Substack, April 25, 2023.

HE MADE IT BACK from the grocery stores. Hardly any food but out two hundred. Juan didn’t mind because he couldn’t. Didn’t lose it on Hot Springs Road either as he passed the spot he pulled a U-turn when the nurse called though the hole in his heart was daring him to poke it. Instead he parked at the bottom of the driveway to unload and sat there in the driver’s seat a good long time with all the windows closed. It was a cold day and the sun was welcome. He stared out at the doorway with its rocks and steer skulls. There were hoes and shovels propped against the wall. A man lives there, he thought, that must be what I am. The setting was quite pleasant, even homey for a jerk with no ambition. He felt he had some though, at least a hankering, which meant that he was sane and anything was possible. And then he saw the door mat as the last view of his life and could he have another, please?

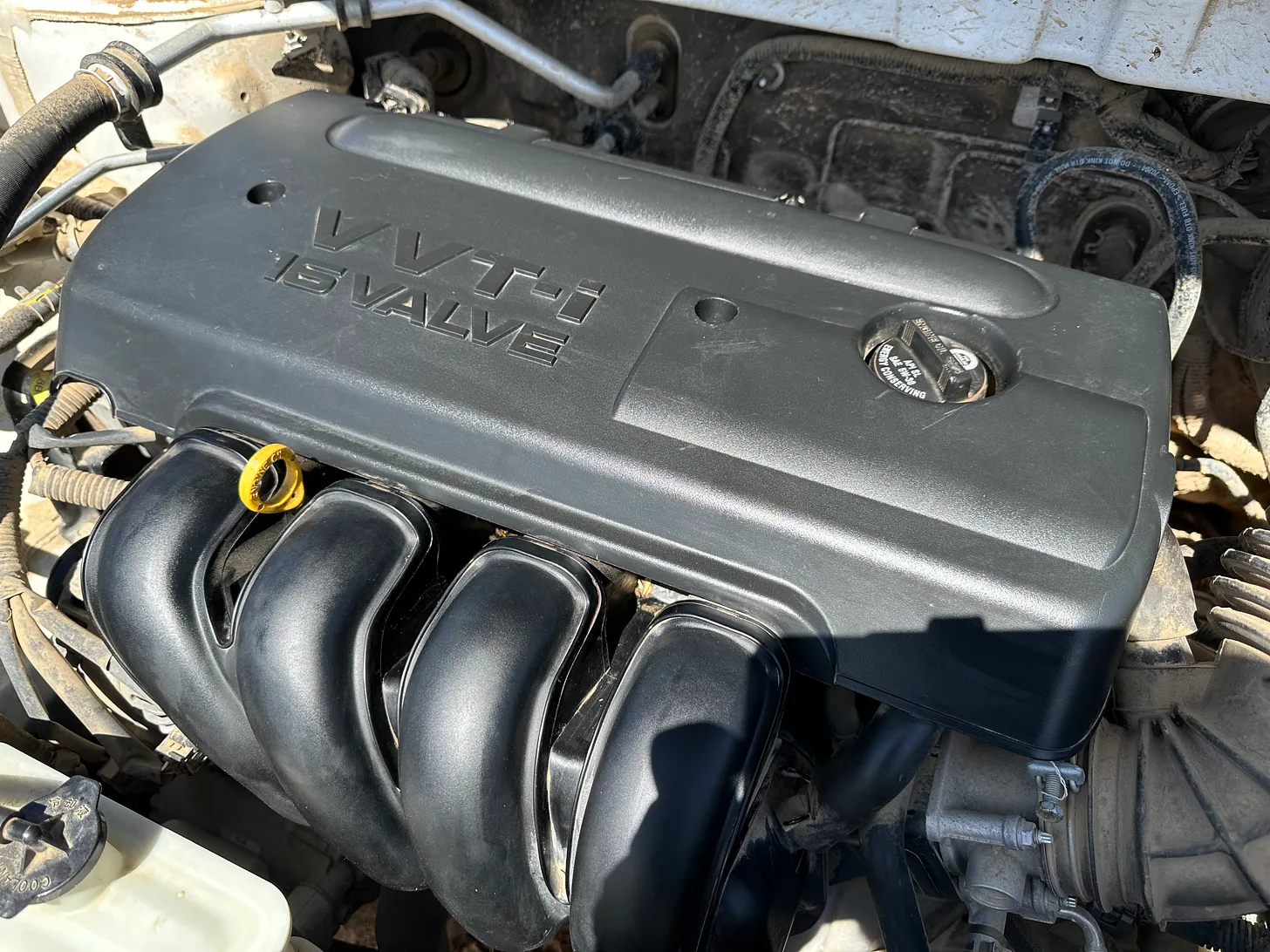

It started as a clicking sound. For the longest time he thought it was the valves. The ‘07 Pontiac Vibe had four per cylinder on the 1.8 liter Toyota engine. As long as they were only clicking, though, he figured he’d be fine. No reason yet to worry they weren’t closing all the way and burning white-hot on the edges. He took a week-long road trip to Iowa bury his wife’s ashes and the thing ran great. A whole year passed. The clicking was a little louder now and every now and then a muted clunk. But still he drove it up to Colorado in the fall, convinced the noises went away when all the parts warmed up and only idiots worried about the things they couldn’t see. The trip was flawless and spectacular. The engine sucked in air and revved like glory all the way home. Even so, at hot idle Juan could still hear clicks and knocks. Time passed like it always does. The days grew short, he switched and mostly drove the truck. It made no funny noises, 4WD was useful in the snow, and the Dodge reached heating temps a mile before the Vibe did. The smaller vehicle was still the economical ride of choice for his trip to Silver City after Christmas. He studied the map and saw the roads where nothing better break, then realized the noise might also be the timing chain, which would not do. The very day before he left he called the garage to make an appointment six weeks down the road and loaded up the truck, happy to have no choice because he loved the roar the V-8 made and never mind the gas. After he came back the Vibe just sat there while he waited. One day Metric Motors finally got their wrenches on it. It took them a whole week.

First spring of its purchase in ‘08, already running a temporary spare

Finally he got the phone call. He don’t know everything they’d done or why it took a week but they were good guys and he trusted them. They’d looked at the timing chain and it was perfect. After much befuddlement, they determined the racket was coming from the air conditioning compressor. To nail this down they’d taken the serpentine belt off and started the engine. Lo and behold, not a click or clunk to be heard. (The belt also drives the power steering and the water pump but the steering and engine cooling worked just fine.) The service manager explained that automotive AC refrigerant also provides lubrication for the compressor’s internal parts. Since he never used the air conditioning at 7,000 feet, the lubricant hadn’t circulated and the compressor had been chewing itself to pieces. Neither their explanation nor anything he googled told him how this could happen with a supposedly free-wheeling compressor clutch and pulley, but they said there were “bits of metal” in the AC system and the whole shebang would need replacing, not just the compressor, to the tune of $2,700 dollars! They assured him that he could certainly still drive until the pulley seized—“If you smell something like burning rubber, that’s what it is”—but then the belt would melt and fall apart and he’d be stranded. He took the car home. If anything the noises were even louder and he knew he’d never drive it again in that condition. The Vibe had been his wife’s car, purchased new. He’d always used full synthetic oil in the engine and transmission. It had never broken down, was fun to drive, and got 35 miles per gallon. Not time to junk it.

The Vibe was actually a Toyota Matrix with a General Motors body. A Twitter friend casually mentioned that he’d bypassed a busted AC compressor on an old truck once by using a special bracket and a shorter belt. Juan hunkered down and haunted online Vibe and Toyota user forums. The amount of bad advice was staggering but here and there a nugget gleamed. He followed the trail back in time to the late 2000s and learned that Toyota used to sell a Matrix model (and Corollas) without AC, whereas the Vibe had always been so equipped. Since the engines were identical, that meant there had to be a part number for a shorter serpentine belt that didn’t wrap around a compressor pulley. Searching databases was a game he played quite well and once he plugged the right words in, he found a forum entry at GenVibe that gave him part #5060605. He didn’t know the brand or whether he could even fix it on his own, but the belt and tools he needed (a 19mm socket plus a 3/8” drive breaker bar) cost less than $70 altogether and the lure of so much cheapness reeled him in.

This is the before photo. The serpentine belt is out of sight on the far left side.

The first thing Juan discovered was the job was basically impossible. He managed to remove the old belt using the 19mm socket and breaker bar to compress the tensioner spring—scary business in itself—and thus commit himself to finishing or having to call a tow truck. But placing the new belt over the power steering pump pulley and scrooching it down to the crankshaft was maddening. There wasn’t any room to place his hands. He couldn’t see. The belt flopped every which way, undoing any progress that he made. No wonder the clerk at the parts store suggested he take the right front wheel off for access through the wheel well. Ha-ha, tho. No way. The sun was going down, too. His tools and flashlight kept falling in the dirt. He’d planned on finishing within the hour but had already taken three. There was blood running down the back of his hand. He hadn’t eaten and it was getting cold. And then he had an idea. Other people had done this just like he was trying unless they lied. He knew how to thread the belt because he’d memorized the diagram. The belt had a mind of its own, though. Well then, maybe listen?

Instead of push, he pulled a little. Here and there a twist to guide it. By keeping just enough tension on the thing to keep it from jumping off the pulleys, he finally got it into place except for at the alternator. By now it was almost completely dark and freezing. He peered into the engine compartment with his flashlight, bending low to follow the track of the belt half a dozen times to make sure he had it right. It ought to go on now, he told himself. Just pull on the breaker bar to get some slack and wrestle the belt over the lip on the alternator pulley. That was all he needed. One last bit. He tried a couple dozen times at least. Another quarter inch of play would do it but there wasn’t any. He carefully laid his tools where he could find them in the morning, lowered the hood, and walked back down the hill. Maybe tomorrow he could do it. Better light, more warmth. A fresh perspective. Not cold or starving. Seventy dollars versus $2,700, come on…

This should tell you something. Alternator pulley above, bypassed AC compressor bottom right.

Editor’s note: see the photo above? The belt is ribbed on one side and smooth on the other. The pulleys where the ribbed side goes have vertical lips (edges) and grooves that match the ribs. The pulleys that take the smooth side have much lower lips and no grooves. Pay attention!

The day dawned clear and sunny with no wind. It was even warmer than it should have been. Juan allowed himself a bowl of oatmeal, the usual hour’s worth of doom-scrolling, and even washed his hair. Procrastination equaled power, he told himself. Only warriors know how to take their time. When he was ready, he walked out into the light, up the hill, and opened the hood. Calmly taking breaker bar in hand, he placed the 19mm socket over the nut cast into the tensioner bracket and pulled until he felt the clunk of full compression on the spring. Keeping the bar pulled tight with his right hand, he grasped the final loop of belt with his heavily gloved left hand and pulled it toward the alternator pulley as far as it would go. The missing quarter inch of slack had not been granted in the night, however, and it simply couldn’t be done. He spent almost an hour trying and walked back to the house for coffee and more research. What he found by using different keywords gave him hope for all humanity.

Everything he’d read about the job, every YouTube video as well, instructed him to place the belt over the alternator pulley last. Everything, that is, except the final post he found. Somewhere in America a real mechanic had entered a discussion and laughed at that advice: “Loop the belt around the grooved alternator pulley and then over the smooth water pump pulley. It’s so much easier!” By now Juan knew every piece of hardware like he’d invented it himself. He walked back up the hill, located the water pump pulley, looped the belt over the alternator pulley, hauled back on the breaker bar, and gently pushed the belt onto the water pump pulley with his bare fingers: good God, it popped right on! Imagine the triumph, the silent hosannas. His hands were beat to hell. There were ugly bruises on his forearms. The sun was streaming down. He felt like singing and wanted to tell the world. Better test it first, though.

Land of geniuses and God

He started the engine. It ran. Very well, in fact. There were no funny noises. He revved it a few times, turned it off, and looked at what he’d done. The belt was still on! He started the engine again and watched it for some minutes. With the shorter belt and one less pulley to turn, the happy four-cylinder ran more smoothly than ever before. Juan was flabbergasted. He took the Vibe on a half-hour run to the top of U.S. Hill in the mountains south of town. There were miles of switchbacks, long grades, and high-rpm climbs in lower gears. If anything, he had more power. At the summit he checked again and all was normal. Really? Oh, yes. The engine ticked like a clock. The Vibe was saved and tons of money, too.

His bruises were like medals. He drove home in a daze and had a nap, doing nothing else all day.

.png)

You must log in to post a comment. Log in now.